TX bushings

TX bushings are self-lubricating bushes compatible with all types of movements (rotation, translation, and oscillation) for high-load applications.

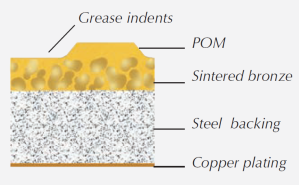

Their composition is as follows:

- A structural steel backing plate to enhance the mechanical strength of the bearing. It is externally protected with a copper plating against corrosion.

- A porous sintered bronze layer that plays a crucial role in thermal conductivity, dimensional stability, and maintenance of the sliding layer.

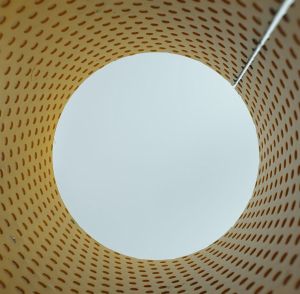

- A sliding layer made of acetal resin (POM) with excellent wear and friction properties. The pockets are used to store the lubricant and help reduce friction during the bearing's operation, thus improving its lifespan.

Lubrification

TX bushes require lubrication. Lubrication is achieved by using grease (or oil) stored in the pockets. A lubricating film is quickly formed, which reduces friction during startup. The TX bushing is well-suited for oscillating movements.

Recommendations

Techné recommends the following conditions for the use of TX bushings:

Variants

The POM sliding layer is replaced with PEEK, which allows meeting the highest temperature requirements for continuous use while maintaining excellent sliding and wear behavior.

Advantages

- Thanks to the excellent abrasion resistance of the POM sliding layer, TX bushes can be used in highly contaminated applications or those requiring low maintenance.

- The TX-PK variant offers a wide operating temperature range (-150 °C to 250 °C) and a good PV factor depending on the operating conditions.

Limitations

- Lubrication is mandatory.

Applications

TX bushes are primarily used for applications with heavy workloads, such as construction machinery or agricultural vehicles.