Quality control

To ensure the quality of the parts, Techné has implemented procedures tailored to customer requirements and specific characteristics of elastomers.

Prototype inspection

Techné inspects its elastomer parts using appropriate equipment.

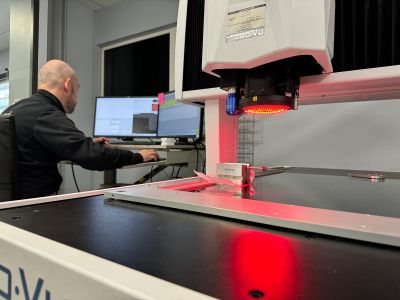

Non-contact dimensional measurements

As elastomer parts are flexible and deformable, Techné employs non-contact measurement machines, either programmable optical 3D or dimensional imaging. They offer precision ranging from 1 to 2.5 microns depending on the measured length. Programming allows for repeated measurements through a fixed protocol. Some devices can be equipped with a contact probe (3D) for parts with rigid inserts (metal, plastic, graphite, etc.) adhered or overmolded.

Customer assembly

If Techné has the final assembly in its possession, an assembly test (and sealing in certain cases) will be performed. Measurement on the assembly may also be conducted, for example, for housing seals.

Optical 3D Measurement

Durometer

Techné durometers measure in IRHD – micro hardness according to ISO 48. Measurements are guaranteed by taking 5 measurements on 5 different pieces (one measurement per piece). When measurement in IRHD is not possible (pieces too small, too thin, or an unsuitable profile), measurements in IRHD or Shore A are performed on plates or pins.

Barotation

Series inspection

For consistency between measurements on prototype parts and series production parts, the same control means are used:

- Non-contact dimensional measurements

- Hardness measurement

- Material inspection

These measurements are performed on 5 samples from each production lot. Some additional checks may be added, such as capability measurements or 100% checks on functional dimensions (only performed with our 100% sorting machines).

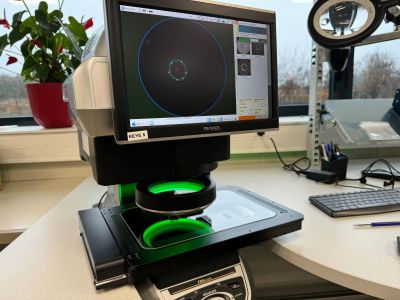

Optical measurement

3D imaging measurement (3D profilometer)

Techné was among the first in France to equip itself with a 3D imaging measurement device, a type of 3D profilometer. This machine allows for virtual cross-sections of parts to check their profile without having to cut or destroy them. This equipment provides the ability to perform non-contact roughness measurements.

3D Optical Inspection: dimension, profile, and roughness Control

3D Profilometer

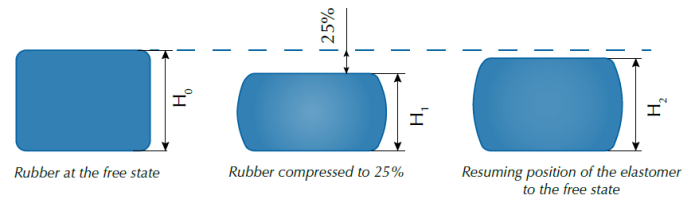

DRC measurement equipment

Techné can offer its clients a measurement of DRC (compression set) frequency (or in some cases for each production lot). DRC is an essential characteristic for sealing joints, representing their shape memory in the compressed state. The lower the DRC value, the better the seal.

Tensile testing machine

Techné has equipped itself with a brand-new, state-of-the-art tensile testing machine to characterize its materials and seals. This equipment measures tensile strength and elongation at break.

Tensile strength represents the force returned just before the elastomer material breaks when subjected to tension. It is expressed in megapascals (MPa) and is a fundamental characteristic of elasticity. This value will be crucial for seals subject to high pressures.

Another fundamental characteristic of elasticity is elongation at break, expressed as a percentage just before the material ruptures. This is particularly important for high-hardness seals that need to be stretched during assembly.

Tensile testing machine with test part